Precious metal refining has come a long way from the crude practices of the past. Today, advanced technologies transform raw precious metal scrap into 99.99% pure gold, silver, platinum, and palladium bars via complex recovery processes. This enables maximum monetary returns even from tiny quantities of these valuable materials.

So, how do innovations in modern refining technology enable such ultra-high purity outputs from complex metal scraps?

Spectral Analysis Testing

State-of-the-art spectrometers utilizing plasma, arc/spark, and x-ray fluorescence accurately analyze scrap composition down to parts per million purity. This enables detailed assaying, so refiners know the exact value of each scrap batch before processing.

Automated Sorting

Intelligent optical, laser, and sensor-based sorting in modern plants quickly segregates complex precious metal scrap into similar batches, optimizing refinement. This preparatory step ensures customized, efficient processing.

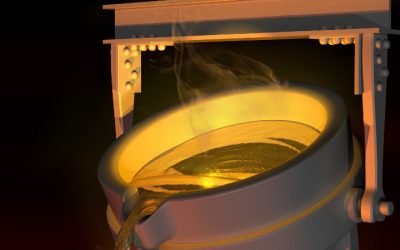

Controlled Environment Smelting

Precious metals have vastly different melting temperatures: gold at 1064°C versus lead at 327°C. So, heating complex scraps needs precise temperature controls to isolate specific metals. Modern induction furnaces with inert atmospheres deliver such accuracy.

Electrolytic Recovery

Purifying precious metal extracts utilizes electro-refining in electrolytic solutions to deposit 99.99% pure gold, platinum, or silver onto cathodes for accessible collection. Sophisticated electrical and chemical equipment enables this essential process.

Responsible Effluent Treatment

Refining uses extensive hazardous chemicals; modern facilities have fully equipped laboratories and scientific teams that treat effluents responsibly before regulated disposal. This upholds ecological standards.

Automated Ingot Casting

Casting molten metals into sellable bars, ingots, or other forms requires careful, controlled cooling. Programmable casting equipment consistently fabricates precious metal bullion to international purity certification standards.

So, modern precious metal refiners leverage complex capabilities via advanced testing protocols supported by automated segregation, controlled smelting, and electrolysis. This delivers maximum yields and 99.99% pure end products from raw scraps efficiently and responsibly. Their innovation upholds both profitability and sustainability. Contact Bay Area Metals today to learn more.